Are You

Facing These?

|

|

|

| |

I am opening a new business and I would like to take care of my wastewater

|

|

|

|

| |

I have wastewater from production but no treatment system

|

|

| |

|

| |

I want to build a waste water treatment plant

|

|

|

|

| |

I have a WWTP but the water seems doesn’t meet the DOE requirement

|

|

|

|

| |

My WWTP is having problems on its equipment

|

|

| |

|

| |

DOE have issued a summon to my factory because of my waste water

|

|

|

|

| |

I have a WWTP but my staff spends too much of time at the WWTP

|

|

|

|

| |

I want to hire a new engineer to take care of my WWTP but how can he get trained?

|

|

| |

|

| |

I want to do servicing to my WWTP but it is so troublesome

|

|

|

|

|

|

|

| |

| Through our decades of experience in Industrial Effluent Treatment System (IETS), a comprehensive solution towards handling your effluent issue is what Reso Engineering capable of. Our services includes, |

| |

Consultation & existing system auditing

|

|

|

Industrial Effluent Characteristic Study (IECS)

|

|

|

Effluent treatability study

|

|

| |

Environmental Quality (Industrial Effluents) Regulations 2009 Written Notification

|

|

|

Wastewater treatment plant operate and manage

|

|

|

Wastewater treatment plant design

|

|

| |

Wastewater treatment plant fabrication and installation

|

|

|

Wastewater treatment plant’s Parts and equipment supply

|

|

|

WWTP competent person guiding and training

|

|

| |

|

|

|

|

|

|

|

| |

Whole Industrial Effluent Treatment System (IETS) Set-up

|

|

|

- Effluent (wastewater) generated by a factory/ plant needs to comply with the regulation set by the Department of Environment (DOE)

- The IETS aim to treat non-complying wastewater by removing or control components that exceed the guideline set by the DOE before releasing it to the public drain

|

| |

| Step 1 |

|

| Solid Screening |

|

|

| Step 2 |

|

| Equalization |

|

|

| Step 3 |

|

| Chemical Reaction |

|

|

| Step 4 |

|

| Solid Liquid Separation |

|

| |

|

|

|

|

|

|

| |

|

| Step 7 |

|

| Discharge/ Reuse |

|

|

| Step 6 |

|

| Water Polishing |

|

|

| Step 5 |

|

| Biological/ Aeration |

|

|

| |

|

|

| |

Consultation of Existing WWTP and Auditing

|

|

|

Detailed survey on the IETS (search for source of problem)

|

|

|

|

|

Come out with findings from the survey

|

|

| |

Provide with direction to cater problem rose

|

|

|

Conduct treatability study with complete report

|

|

|

|

|

| |

Built, Operate and Manage (Outsourcing Management)

|

|

|

Reso undertakes on design, constructing, operate and manage of the wastewater treatment plant

|

|

|

|

|

We will be stationed at the WWTP to operate and manage it

|

|

| |

Factories shall focus on what they do best, production of products

|

|

|

|

|

|

|

| |

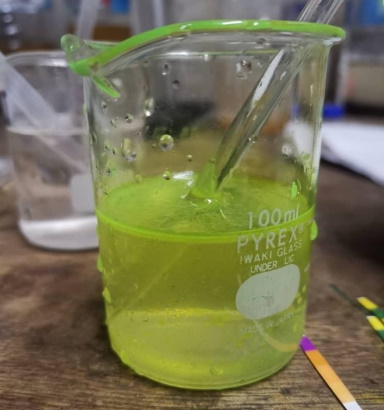

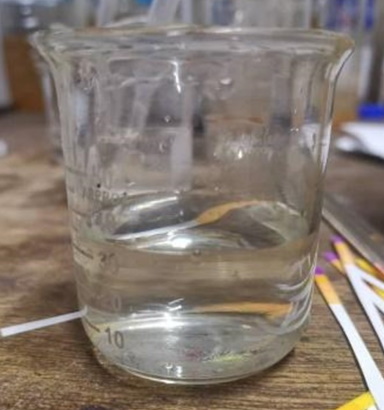

Effluent Treatability Study

|

|

|

| A study done by our in-house lab professional to ensure wastewater treatment plant to be invested shall perform according to their needs |

| |

- The right procedures and scale of procedures

|

| |

| Step 1 |

|

| Oil separation |

|

|

| Step 2 |

|

| Type and amount of chemical dosage |

|

|

| Step 3 |

|

| Aeration time |

|

|

| Step 4 |

|

| Filtration and etc would be integrated |

|

|

| |

- The full study is recorded and documented for the use of future reference by clients

|

| |

|

|

|

|

|

|

| Raw Wastewater |

|

Partially Treated Wastewater |

|

Fully Treated Wastewater |

|

| |

Industrial Effluent Characteristic Study (IECS) Required by DOE

|

|

|

| Working with our strategic partner, a 3 days wastewater generation study from a factory shall be conducted. A study to determine, |

| |

Waste Water Chemistry

|

| Properties of waste water |

|

|

Waste Water Flow Rate

|

| Waste water generation from production facility |

|

|

Waste Water Flow Pattern

|

Flow pattern of waste water generated

Example 2m3 at 10am, 4m3 at 4pm |

|

|

| |

WWTP Competent Person Guiding and Training

|

|

|

| Reso is experienced in training staff from basic to advance knowledges in order to be a well-equipped competent person for WWTP. Training exposes the staff to, |

| |

WWTP important theoretical knowledge

|

|

|

Highly practical on-site skills to manage the WWTP

|

|

|

DOE Wastewater compliances to be taken care of

|

|

|

| |

WWTP Equipment Servicing

|

|

|

| Reso offers the service of periodically servicing which may be troublesome to factory personnel such as, |

| |

|

|

|

|

|

Equipment’s wear and tear parts replacement

|

|

| |

|

|

|

|

|

|

|